After that project, I wasn't able to do much for a few months. Finally back at home, time for the engine! And many, many, many small little "details" that seemed to be overlooked until I put the engine in.....Like fuel line routing, ignition, oil filtration and cooling....not to mention fabbing mounts, brackets, and doo-hickeys for all these things (nothing you guys have run into before, I'm sure

.

Time for a little aside, because, I'm sure I will be flamed for the placement of a few of my doo-hickeys. I've put a lot of thought into this, and what and how the buggy will be used. It will be hurt fairly often, and driven very hard over many different types of terrain. So, I came of with a few "rules" for the build of this, my first dune baggy, and first VW.

1- Chassis, running gear, and engine/engine components stay together.

2- Body, electrical, etc stay together.

What this means is, when I remove the body, (after dissassembling the cage, of course) I only want to have to disconnect a few wires (alt, battery, and engine leads, remove the body bolts, and voila! Body comes off. I also don't want to have to start mounting things to the rear portion of the cage (mainly engine electrical, etc). So, these rules have made some compromises necessary. Please, before you flame me, keep this in mind. HOWEVER, should you see I have made a GLARING or dangerous error, feel free to let me know, in whatever manner you choose! Thank you

OK, here the heart of my beast-

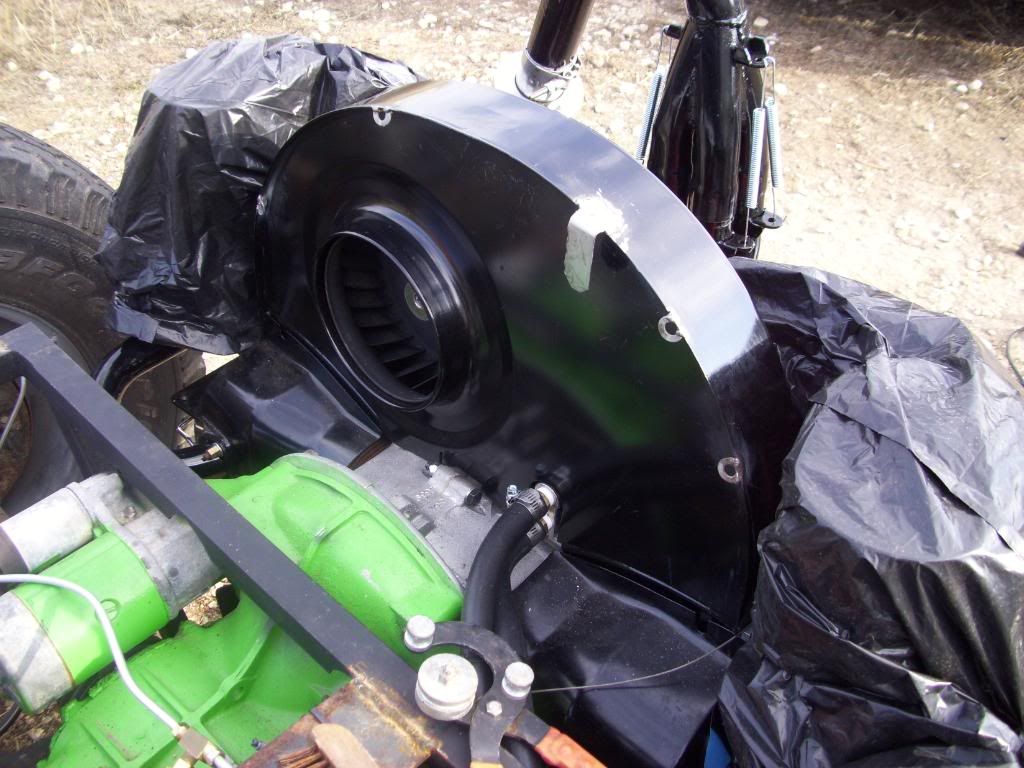

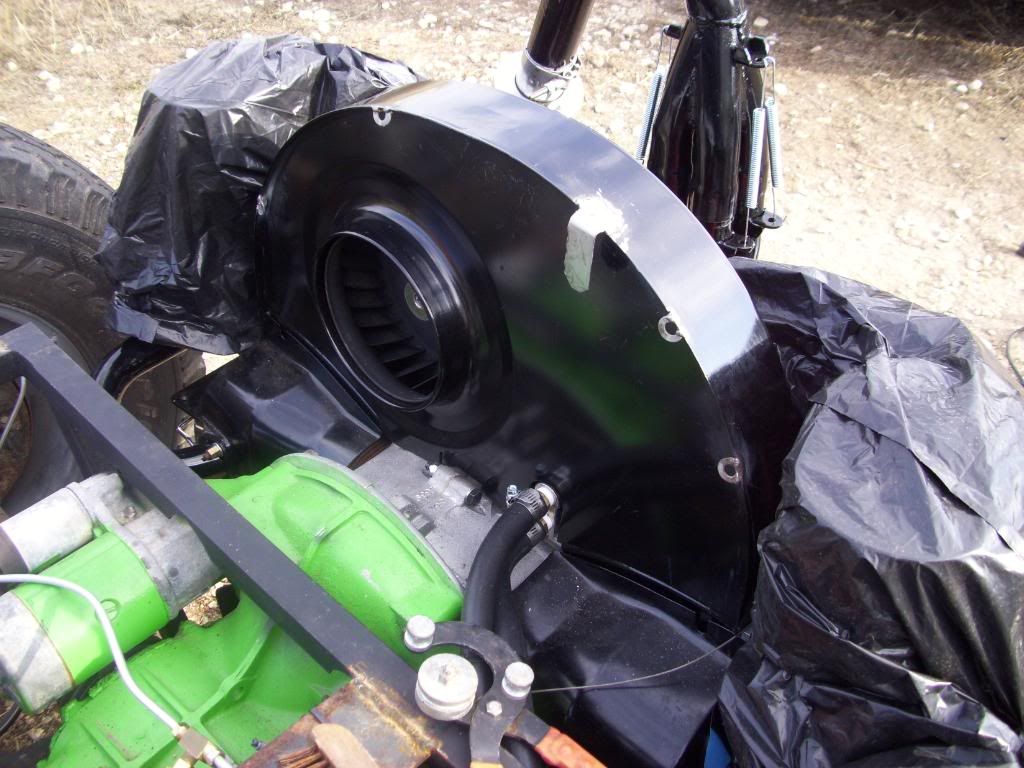

2276cc, with 5.5 I-beam rods, 40x35 heads, and cam changed to Engle VZ-25. Currently NA with 2xWeber 44's. I am fairly certain this will change next winter when I install the turbo, and go to either mechanical or electronic port injection. However, she is NA now, and here she is in the buggy, at long last-

Then I needed to mount the oil filter, and oil cooler (with powered fan). I wanted somewhere inside the frame rails for protection, but that would fairly easy to get to and change filters. I also needed a location away from things (like rocks) that would poke nasty holes in them (or rip them off), so it had to be fairly high. I decided I would build mounts above the transaxle and on the drivers side-

With that complete, I turned my attention to the fuel line. I've had a vehicle burn before due to rubber fuel line....so I NEVER run any anywhere near the engine as a consequence. However, with the exposed nature of a buggy, and the lack of fenders, firewalls etc, for me to mount to, I again had to exercise my creativity (for all I know, I am just re-inventing the wheel, but I FEEL creative, so there!)-

I fabricated a mount for the "T", then welded some washer along with the "T" mount to the doghouse. I then painted everything gloss black to match the doghouse, and the oil cooler and filter mounts flat black.

Then I had to make a mount for the CDI and coil....This nearly defeated me. I have no mill, no metal brake, no one near me that is a certified aircraft welder (just playing, Tom

). So I sat, looked the the "engine bay", whilst (I love that word) playing with the aforementioned CDI box and coil. Inspiration struck me. I went inside and grabbed some parts from and old computer case I had save (god knows why.....) and then spent another very frustrating 8 hours fabricating.....Unfortunately, I took no pics during the process, and only have the completed product-

As you can see, the mount is made from aluminum, with a welded stiffener that you cannot see, between the coil and the CDI, with bolts from both items going through it. The coil and CDI are actually mounted to plexiglass (because I wanted to see how it would look). The aluminum is painted with wrinkle paint, matching the fan cover, done to set it off from the gloss black of the doghouse and tins. I wanted a very "simple" look, and will stick with varying textures of black, and billet aluminum where I can.

I also prepped and painted the dash in wrinkle paint. The dash insert will be engine turned stainless steel (to be done when I have finally made my gauge selection (details, details, details)

Hopefully soon, TexasBuggies will have time to see me and build my cage, I want to do that before I permanently mount the body and complete the wiring. However, I still have the 2" body lift to fab, and some frame horn rust to combat (how in the hell did I miss THAT???)

Sorry for the long post, I hope you enjoyed it in at least some way :-)

This IS my sig......